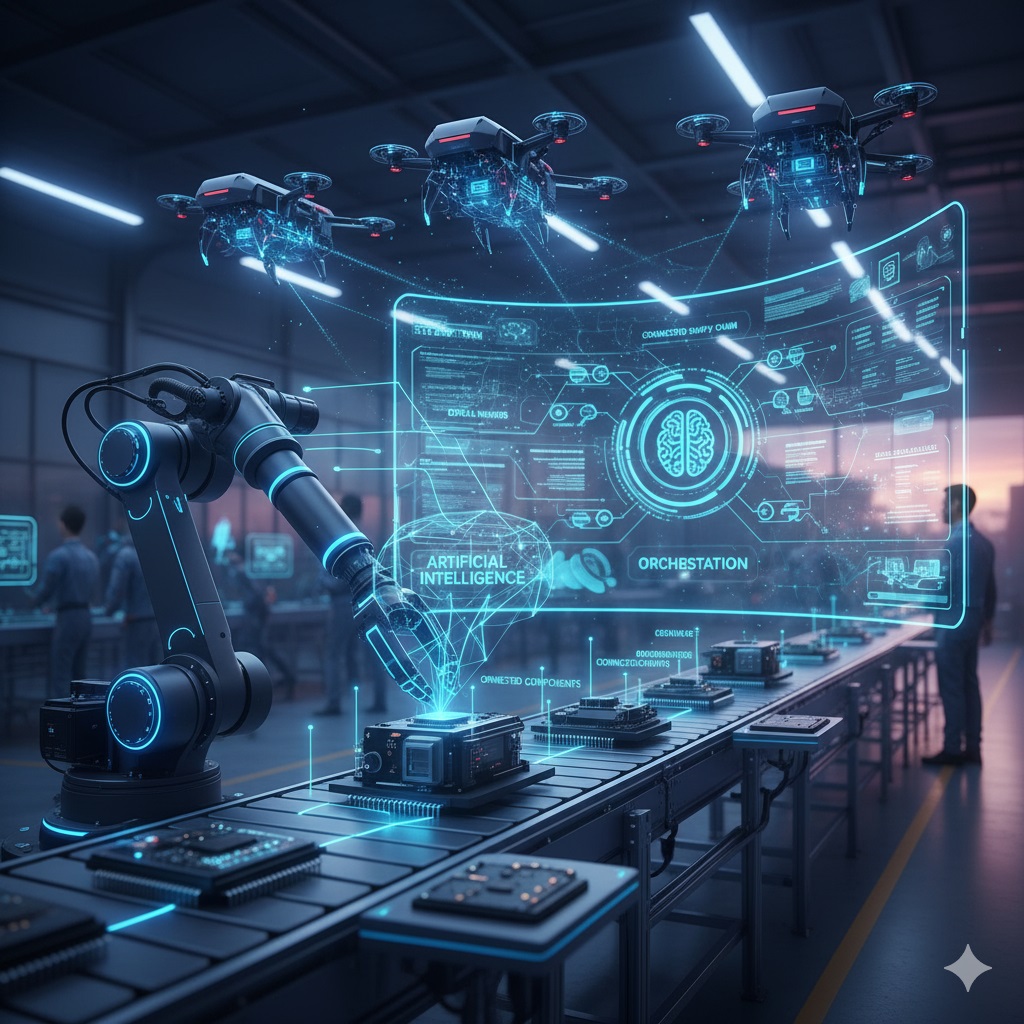

What It Is: Manufacturing continues to move rapidly down a continuum from the highly manual to the digital, from disconnected, asynchronous activities to integrated, orchestrated actions, across an ever-expanding and diverse set of components

Why It Matters: Defining a holistic strategy that enables agility and flexibility, that provides structure without limiting innovation, can be a highly complex activity, but one that is well worth the investment given the right strategy can unlock value in multiple ways (production capacity, productivity, improved quality and safety, etc.), particularly in situations where there is a diverse footprint in place

Key Concepts

- Design with a framework in mind, that is intended to connect, monitor, track, orchestrate, and optimize performance within and across digital facilities

- Establish data ownership, data management, and data governance to enable long-term value

- Think of individual facilities as having varied configurations of logically common components

- Manage individual components so that they can be relatively commoditized and replaced easily

- Understand that the goal is to optimize the overall system, harmonizing workers and equipment

- Design the framework to enable adding individual components rapidly, with minimal disruption

- Leverage the framework to create an environment that can simulate changes pre-deployment

- Define strategies to insulate legacy equipment so that it integrates the same as modern assets

- Work with OEMs to facilitate transition between bolt-on analytics to intelligent equipment

- Integrate AR where it provides incremental value without adding complexity / distraction

- Reduce complexity with AI, enabling operators to be more productive, effective, and safe

- Integrate learning and development content dynamically based on operator experience

Approach

- Provide required internal/external connectivity, infrastructure, and monitoring across locations

- Identify connected components across facilities by function (equipment, devices, sensors, etc.)

- Define relevant personas and capabilities to enable digital workers (shop floor to facility leaders)

- Architect the environment to treat individual components as actors in a connected ecosystem

- Identify integration standards and relevant characteristics per component to enable analytics

- Design facility data solutions to allow for structured and unstructured data aligned to the cloud

- Establish an infrastructure for orchestration that can coordinate activity across connected actors

- Gather, analyze, and optimize processes given performance data and operating characteristics

- Analyze observations centrally to leverage insights and opportunities across similar facilities

- Extend the boundaries of orchestration incorporate customers, suppliers, and partners

For Additional Information: Transforming Manufacturing

Excellence doesn’t happen by accident. Courageous leadership is essential.

Put value creation first, be disciplined, but nimble.

Want to discuss more? Please send me a message. I’m happy to explore with you.

-CJG 11/19/2025